Overview

INTRODUCTIONPhenix Energy Group has been created to capitalize on the significant current and projected growth in Asia’s energy demand by providing an improved and cost effective method of transporting petroleum products from the Caribbean. At present petroleum can only be transported from South America to Asia via three routes: 1. Through the Panama Canal: The Panama canal can only handle very small oil tankers at a cost per barrel significantly higher than a VLCC super tanker; No shipments are being made at this time to Asia through the canal. 2. Around South America using frequently closed routes; there are only two to three months a year that this route can be used. It has been removed from most shipping companies route maps. 3. Around the southern tip of Africa utilizing a very long route currently being used to ship oil from South America to Asia. This route takes 76 days one way vs. Phenix’s 46 day route.

Currently it takes approximately 76 days of one-way transportation time to ship crude oil from Venezuela to China and 75 days to Japan. Once operational, the Atlantic to Pacific Pipeline Project's 46/41 day route not only saves money on the transportation of the products; it also reduces the need for tankers by approximately 50%. The Atlantic to Pacific Pipeline Project offers significant benefits over currently available transportation methods in the region. The pipeline delivers:

• Dramatic cost reductions;

Currently the largest vessel that can transit the Panama Canal is called a PANAMAX tanker with a capacity of about two hundred thousand barrels (these ships range from 50,000 - 80,000 dead weight tons in size), this is in direct contrast to a VLCC (Very Large Crude Carrier with 300,000 to 500,000 dead weight tons) which can hold more than 2 million barrels. The Atlantic to Pacific Pipeline Project reduces dependence on a vital world oil transit chokepoint. The Panama Canal has been identified as a world oil transit chokepoint due its potential for closure. Disruption of oil flows through a chokepoint route can have a large impact on world oil prices. Phenix employs "state of the art" technology installed during the construction of the project, in the area of safety, security and control systems, thus avoiding or minimizing operational failures, mechanical failures and corrosion during the operation of the project. These sophisticated features continuously monitor pipeline operation to immediately respond to any changes, mitigate environmental impacts and optimize construction and operation of the Atlantic to Pacific Pipeline Project. The Atlantic to Pacific Pipeline Project consists of two marine terminals located on the Atlantic and Pacific coasts. Connection between the super tankers and the terminals is established via deep water off shore mono-buoys. Each marine terminal is equipped with storage facilities with a capacity of approximately 10 million barrels for the entire system.

The pipeline system consists of parallel pipelines for crude oil. The target throughput for the system is 4.2 Million barrels of product per day. Pumping and valve stations are situated in each Marine Terminal for transferring products from storage facilities to the appropriate pipeline. Additional pumping and valve stations are located along the pipeline in order to maintain product flow and pressure. Each pumping and valve station has its own power plant with sufficient generating and backup storage capacity to operate each pumping station. All of the pumping and valve stations are protected by automatic foam and high pressure water fire suppression systems. In the case of a leak, an automatic system of pressure sensors in the pipeline uses a fiber-optic link to inform the OCC and to close off the emergency valves in the section affected, automatically shutting down the affected line at the pumping stations.

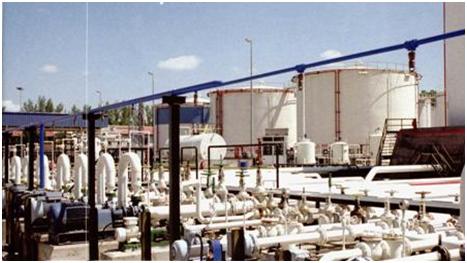

The Marine Terminal Tank Farms are located on both ends of the pipeline at the Atlantic and Pacific coasts. The connection between tankers and the terminals are via offshore mono-buoys situated in deep waters to safely accommodate supertankers (VLCC). Each terminal has a storage capacity sufficient to support the peak demand of the clients for petroleum products. Storage facilities are constructed according to state of the art standards, including discreet compartmentalization, protective dikes, surface water monitoring and protection, fire suppression, and tropical storm/hurricane resistant structures. The Marine Terminals consist of storage tanks, pumping stations, administrative offices, stores and maintenance shops. A Permanent Terrestrial Emergency Team and a Permanent Marine Emergency Team are based within each Marine Terminal. The connection between tankers and the terminals is through the offshore mono-buoys situated in deep waters to safely accommodate supertankers (VLCC).

ENVIRONMENTAL ISSUES

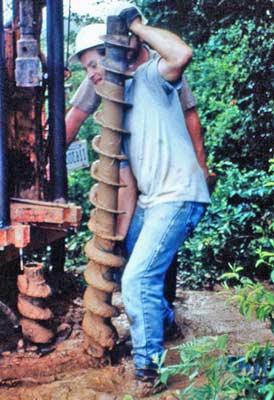

Phenix Energy Group approaches environmental issues proactively, instead of waiting for challenges from the environmental community. Phenix has implemented environmental systems that work with the environmentalists; systems such as Ultra modern security systems to secure the pipelines from leakage and vandalism. In addition we use our fiber system to provide real time ecological monitoring along the route. Phenix has retained the services of Golder Associates, one of the largest privately held engineering and environmental science consulting companies in the world. They have already performed services for Phenix Energy Group and stand ready to assist us when construction is underway. With offices in Asia Pacific, Australia, Europe, North America and South America, Golder Associates is able to assist us in meeting all the environmental requirements for this project. A state of the art sophisticated redundant safety system for monitoring pipeline pressure, product temperature and equipment status, along with real time video monitoring, connected by fiber optics will be installed along the line and at all pumping and valve stations for systems automation, leak detection, maintenance and operational purposes. During operations, the working pressure of the pipeline will be +/- 42 kg/cm² (600psi). Solid state microprocessor monitors detect pressure variances of 10% to 15%, automatically closing the safety valves and shutting down the pumping stations via the fiber optic link. In general, 2.5m deep trenches are excavated for the pipeline and then back filled with the excavated material. Topsoil stripped from the work area excavation is used for the final 15cm of backfill to promote the re-establishment of the natural vegetation. The same excavation process is used for isolated rural roads and paths, where there will be little impact to traffic, and dry or small streams where it is economical to do so. In the case of main roads, rivers and large streams, a horizontal boring machine is used to bore under these features and insert casing for the pipes.

For systems support, an integrated fiber optic cable located along the entire length of the pipeline transmits real time sensor and safety system data (flow, pressure and temperature). Operational data is analyzed and processed in the Operations Control Center (OCC). Automated systems instructions are transmitted to the safety and pumping and valve stations from the OCC. The Operational Control Center (OCC) operates 24 hours a day. Phenix is working with CENS, a US National Science Foundation Science & Technology Center, which is developing Embedded Networked Sensing (ENS) Systems and applying this revolutionary technology to critical scientific and social applications. Like the Internet, these large-scale, distributed systems, composed of smart sensors and actuators embedded in the physical world, will eventually infuse the entire world, but at a physical level instead of virtual. The CENS focus for ENS Technology Research draws on a diverse set of researchers within engineering, from distributed system design, to distributed robotics, to wireless communications, signal processing and low-power multi-modal sensor-technology design. In addition, the physically-embedded nature of this technology calls for significant experimentation and exploration within the context of the target application domains in order to identify the true challenges and opportunities. CENS technology research is currently focused in the following eight areas:

The CENS focus for ENS Application Research is currently on four experimental application drivers: ecology and habitat sensing, seismic sensing and structure response, monitoring and modeling contaminant flows, and detection and identification of marine microorganisms. To support this scope, CENS combines the expertise of faculty from diverse engineering disciplines with the expertise of biological, environmental and earth scientists. During the lifetime of the Center, the plan is to pursue additional opportunities for applying the technology to other natural and engineered systems. A multifaceted education, outreach and training program ensures that CENS and our research products, software, and technology/application research optimally benefit the target communities. Three of the four CENS Applications Research areas focus on Ecological and Habitat Sensing to monitor the dynamics of biological complexity: environmental, organismal, and cultural conditions, and the interactions between them in natural and managed landscapes. The overall goal continues to be improving the design and deployment of embedded network systems for practical ecological, terrestrial, marine, and agricultural uses that can operate remotely, and in uncontrolled natural settings, capturing chemical, physiological and environmental data across a wide range of ecological conditions, temporal and spatial scales. Significant work has begun in the effort to provide an infrastructure to field test Embedded Networked Sensing (ENS) and techniques within a range of habitats and ecosystems (including in the tropics), and to deploy experimental model systems suitable for addressing specialized and general ecological information needs. CENS is near the completion of new software that will enable us to increase the array to more than 100 nodes and thousands of sensors. A robust, 10 channel video network to observe avian behavioral activities related to climate, nesting and reproduction. Soil mini-risottos and below ground sensors and cameras are being designed for measuring soil moisture, nitrate, CO2, temperature, and root/fungi activities in response to weather. And finally, the first permanent networked info-mechanical system (NIMS) node was installed within the forest canopy and spanning a riparian ecosystem. Research Highlights: Micro climate Sensor and Video Enabled Networks:

1) The Continuous Measurement System project is intended to investigate the requirements for a long-term data collection by deploying a system with simple, well-tested communication software and a limited number of nodes. 2) The ESS is designed to be the test bed for sensors, interface hardware, RF communication hardware, communication protocols, databases and user interfaces to be used in CENS Habitat sensing. 3) The system will support characterization of microclimatic influences on nesting activity and nest success 4) The data gathered is used to test systems for automatically classifying nest box images in real time at remote nest sites. Embedded Network Sensing within Soils: 1) A networked robotic mini-rhizotron array is being developed for obtaining real-time, simultaneous field data on root/mycorrhizal dynamics in conjunction with soil respiration (CO2), nutrient flux (N, P, etc.), and moisture. Current minirhizotron cameras are cumbersome to operate and are very time-consuming during data collection, management, and interpretation. 2) However, they provide valuable in situ observations impossible through other means 3) The soil array is used to investigate the effect that diurnal temperature changes have on water movement through soil and how that water movement is affected by the presence of rocks on the soil surface. 4) A second ESS-based micro-climate and soils monitoring system deployed in a botanical garden supports the study of the micro-climate and soil preferences of traditional and contemporary Honduran crops of cultural, medicinal, and economic significance. 5) Conducted a successful Soil Sensing Workshop to bring together experts in the field, the culmination being a proposal submitted to the NSF as well as a paper written for the journal BIOSCIENCE. Other Related Projects: • Ecophysiological studies utilizing Mobile Sensor Platforms HUMANITARIAN ISSUESLarge infrastructure and energy projects and the substantial revenues they generate do not always deliver the fullest benefits at the local level. This failure is sometimes called the "Paradox of Plenty". Phenix Energy Group has committed to sharing the prosperity. The integration of locals into the work force, inclusion of the communities in the process, and operating in harmony with the environment are among the Company’s highest priorities. Phenix initiates contacts with the indigenous communities along the proposed route to educate them about the project and to assure that their concerns, social and environmental, are satisfied from the outset of the project. An integral part of the overall Phenix plan is to give back to the people of Central America through a well planned and managed Humanitarian effort. Phenix allocates a percentage of its profits generated in the host country to direct humanitarian efforts in the country. This effort is managed through a non profit organization separate foundation. Funds are administered according to the same rigorous accounting methods applicable to the Company. None of the funds are distributed in cash, but rather go directly to projects administered by private contractors demonstrating adherence to the highest ethical standards.

Examples of projects that positively impact the quality of life of the people of the host country include local medical clinics, schools, fresh water wells, multi-purpose community centers, electric generating and distribution facilities, job training, transportation and communication infrastructure, and free or low cost connectivity programs. The goal is to provide opportunities for the people to improve their quality of life and to help them help themselves. Benefits of the Phenix Project to the host country: Phenix provides the country with many benefits, such as reductions in poverty, increases in the employment base, providing accessibility for students to permit them to receive information and education through better access to the Internet, providing medical services to outlying areas, training laborers so that they can work in better paying jobs, etc. The Atlantic to Pacific Pipeline Project ‘trickles down’ directly to approximately 2,200 people who are indirectly impacted by Phenix using as much local services as possible. They will include employment in business such as:

| ||||||||||||||||||||||||||||||

|